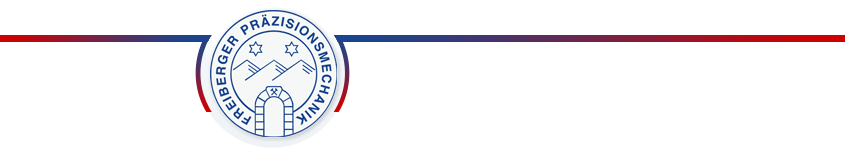

You need highly precise and complex parts and components? Then we are the perfect partner!

Being a well-established manufacturer of precision parts and supplier of surveying instruments, the making of highly-precise parts and their assembly into complex component groups are the focus of our daily activities.

Thanks to our profound knowledge in the manufacturing of optical-mechanical precision parts we have been able to establish long-lasting business relationships with companies in the optical-mechanical industry, semiconductor, electronical and analytical measuring industry as well as renowned research institutions.

By utilizing state-of-the-art technologies and machining centers we are able to realize the manufacture of precision parts and the assembly of component groups with the highest level of accuracy. It is our priority to make sure that your items as well as ours (quantities between 1 and max. 1,000 pieces / many different metal and plastic materials) are at all times made with a continuous high quality standard.

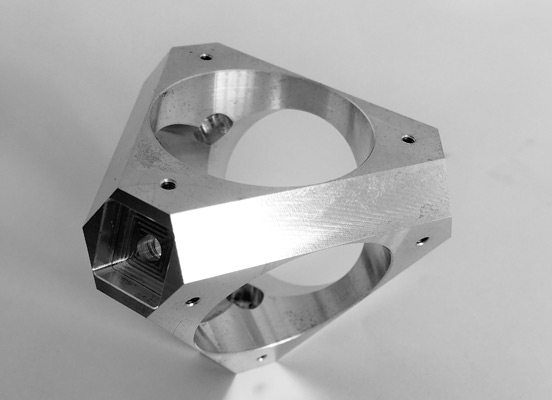

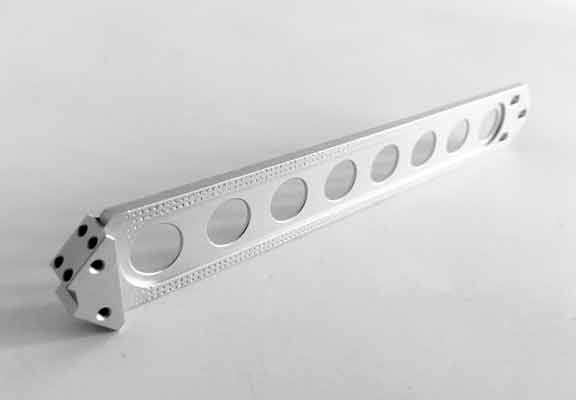

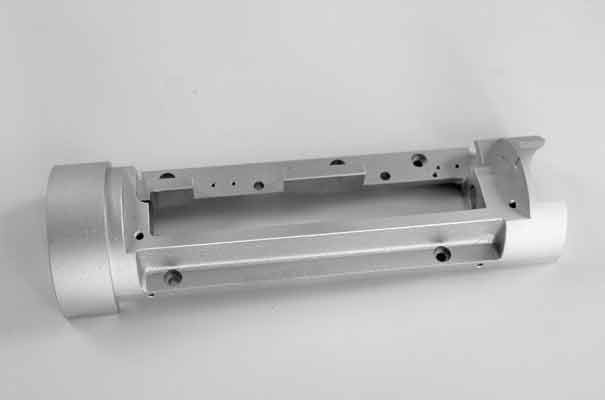

5 – Axis CNC Milling

- configured with 225 tools

- simultaneous machining

- 3D and free form milling

- positioning accuracy of ± 2 µm

- max. work piece weight 20 Kg

- travelling distances X 350 | Y 500 | Z 300 mm

- 20.000 hours p.a. machining capacity thanks to automated manufacturing

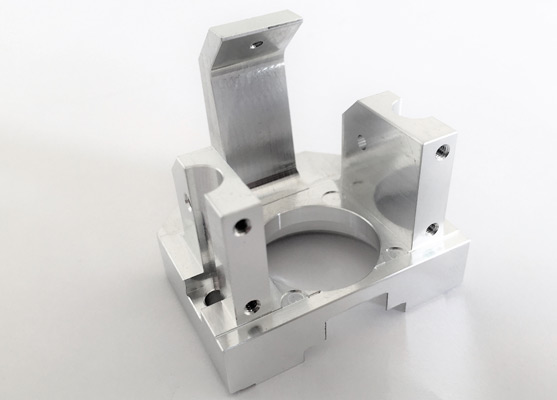

3 Axis and 5 Axis CNC Milling with ATS

- simultaneous machining

- positioning accuracy 5 µm

- travelling distances 3 Axis X800 | Y 500 | Z 610 mm

- max. work piece weight 5 Axis 15 Kg

- travelling distances 5 Axis X320 | Y 320 | Z 250 mm

- 50.000 hours p.a. machining capacity thanks to automated manufacturing

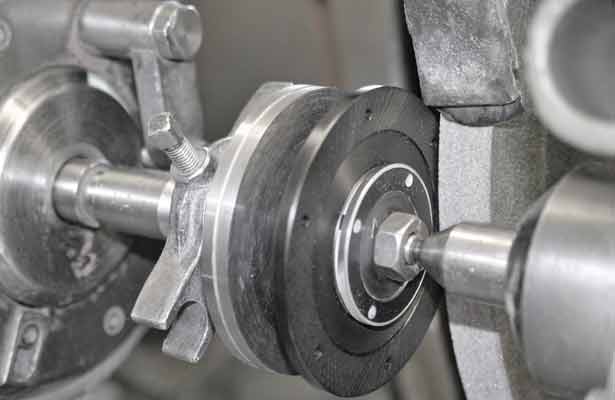

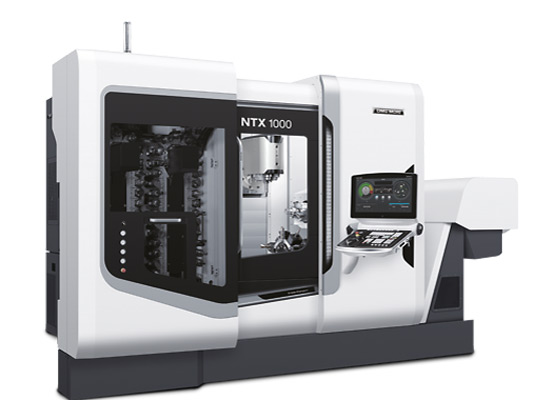

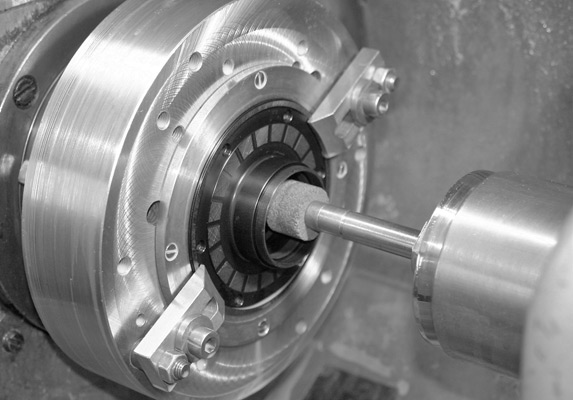

9 – Axis Turning And Milling

- positioning accuracy 5 µm

- max. draw tube inner diameter 65 mm

- turn & mill in one setting

- max. turning diameter: 350 mm, max. turning length: 600 mm

- 6.000 hours p.a. machining capacity thanks to automated manufacturing

CNC Turning

- positioning accuracy 5 µm

- max. draw tube inner diameter 65 mm

- number of driven tools: 6

- max. turning diameter 350 mm, max. turning length 600 mm

- 12.000 hours p.a. machining capacity

Grinding

- urface grinding 200 x 600 mm

- internal grinding Ø 4 – Ø 125 mm x 175mm

- cylindrical grinding Ø 1 – 180 mm x 600 mm

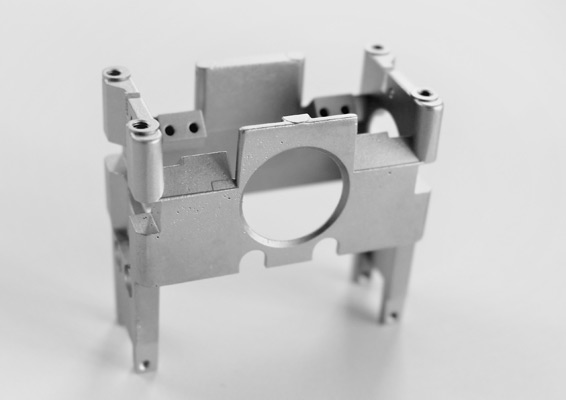

Component Assembly | Finishing

- vibratory finishing

- decorative anodizing

- laser engraving X 600 mm Y 375 mm Z 380 mm | max. 10 kg

- high gloss polishing, materials: stainless steel, bronze, brass and plastics

- assembling, adjusting and testing of optical-mechanical component groups

- assembling of complex component groups in a nearly dust-free environment

Materials

- broad variety of basic materials in stock

- stainless steel, tool steel, noble metals

- aluminum, brass, copper and special alloys

- plastics PEEK, PEEK Carbon, POM, PTFE and polyamides

- exotic materials like invar, tantalum, titanium, zirconium and nickel based alloys

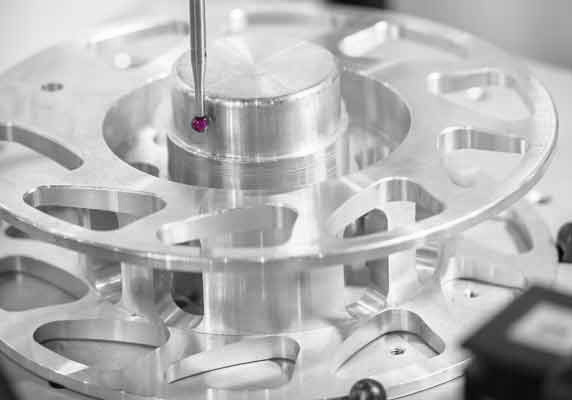

Measuring Equipment

- temperature chambers and vibration test rig

- issuing of first-sample inspection reports

- 3D coordinate measuring machine | measuring accuracy 2 µm

- X 650 mm Y 750 mm Z 500 mm

- 2 coordinate measuring machine, optical UMM | resolution 0.2 µm

- measurement area: X 150 mm Y 100 mm

- length measuring device, optical ULM | resolution: 0.1 μm

- max. part diameter: 0 … 50 mm | measurement area: x = 0 … 450 mm

Your project | part or component group require even tighter tolerances, better quality of the surface finishing or need to be made of a very special material? Please feel free to contact us! You will benefit a lot from our experience and together with you we will develop the perfect solution and make it happen!